Conveyor systems are the unsung heroes of countless industries—mining, agriculture, manufacturing, and logistics all rely on them for smooth, continuous operations. However, without the right components, even the best conveyor system can suffer from inefficiencies and unexpected breakdowns. That’s why choosing the right conveyor belt accessories suppliers in Sydney is crucial for businesses that depend on productivity, safety, and reliability.

Why Conveyor Belt Accessories Are Essential

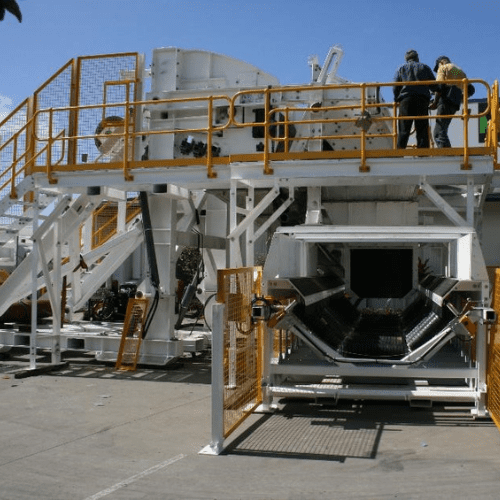

Every component in a conveyor system plays a vital role. While the belt itself does the heavy lifting, it’s the supporting accessories that keep everything running efficiently. These include skirting systems, belt trackers, impact beds, rollers, clamps, and other components designed to reduce spillage, minimize wear, and extend equipment life.

At TS Global, we provide a comprehensive range of conveyor belt accessories in Sydney, helping industries maintain consistent output with minimal downtime. Whether you’re upgrading an old system or building a new one from scratch, our accessories ensure optimal performance, even under the toughest operating conditions.

The Importance of Conveyor Belt Scrapers

One accessory that plays an especially important role is the conveyor belt scraper. Without proper cleaning systems in place, material carryback can lead to buildup on pulleys and rollers, causing misalignment, excessive wear, and even system failure.

Our conveyor belt scrapers in Sydney are designed to effectively remove any remaining material from the belt surface after the discharge point. TS Global offers a range of scraper solutions, including:

Primary Scrapers: Positioned at the head pulley, these remove most of the material.

Secondary Scrapers: Installed further down the belt to remove residue left behind.

V-Plough Scrapers: Protect the tail pulley by clearing material from the return side.

Crafted from durable polyurethane and tungsten carbide materials, our scrapers are built for high performance and long service life.

TS Global – Leading Conveyor Solutions Provider

When it comes to quality and expertise, TS Global stands out among conveyor belt accessories suppliers in Sydney. Our reputation is built on decades of experience, technical know-how, and a strong commitment to customer satisfaction.

Here’s why industries across Sydney trust TS Global:

Comprehensive Product Range: From scrapers to rollers and beyond, we offer complete conveyor solutions.

Engineered for Performance: Our products are designed using the latest technologies and tested in real-world conditions.

Expert Consultation: Not sure which accessory or scraper you need? Our team is ready to help with customized advice.

Fast Delivery: We understand the cost of downtime, so we work quickly and efficiently to get you what you need.

Supporting Sydney’s Industrial Backbone

Whether you’re operating in mining, agriculture, food processing, recycling, or manufacturing, TS Global provides accessories and scrapers that meet the unique needs of your sector. Our clients rely on us for products that not only fit seamlessly into their conveyor systems but also improve performance, reduce waste, and enhance safety.

Partner with TS Global Today

Don’t let inefficient conveyor systems hold your operation back. With the right accessories and cleaning systems in place, you can reduce downtime, cut maintenance costs, and extend the life of your equipment. As a leading conveyor belt accessories supplier in Sydney, TS Global is here to deliver the solutions you need.

Get in touch with our team today to learn more about our conveyor belt scrapers in Sydney and how our tailored accessories can keep your operations moving forward.